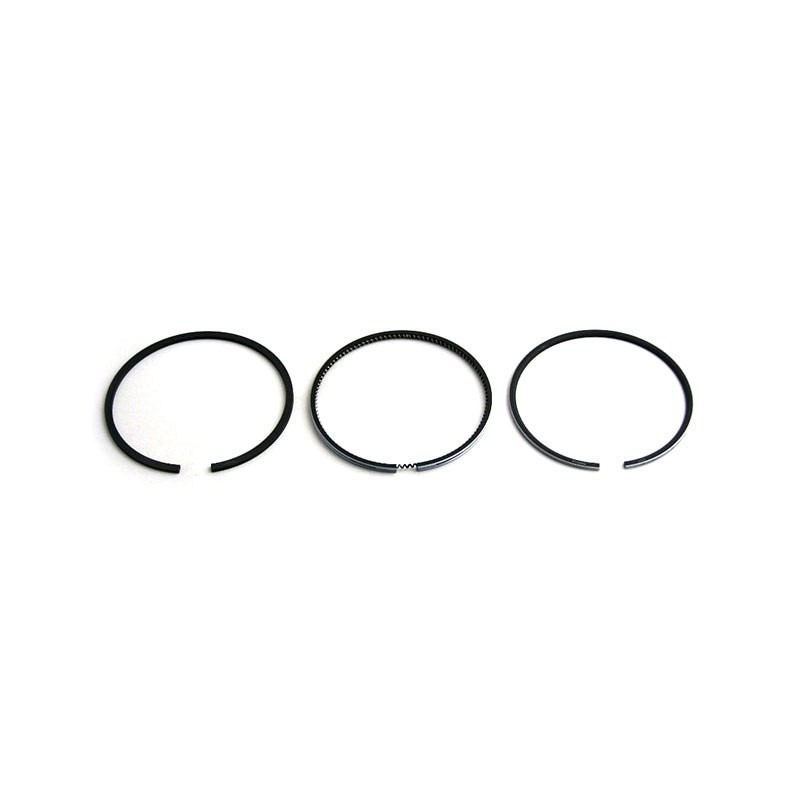

900005236 .020 Ring Set For Yale Forklifts

Product Description

If you are looking for a high-quality ring set for your Yale forklift, look no further than the 900005236 .020 Ring Set. This ring set is designed to fit in the cylinder of your Yale engine and provide a tight seal that prevents gas leakage and improves performance. The ring set is made of durable materials that can withstand high temperatures and pressures and is easy to install.

THIS PART IS ALSO LISTED UNDER THE FOLLOWING PART NUMBERS: 900005236 YT 900005236 YALE 900005236 YALE900005236 900005236.

.020 Ring Set

Product Specifications

The specifications of this .020 Ring Set are mentioned below.

Condition | New |

Brand | Aftermarket |

Part Type | Ring Set |

Size | .020 |

Manufacturer Part Number | 900005236 |

Compatible Equipment Type | Forklifts |

Compatible Equipment Make | Yale |

Features and Benefits

Provides a tight seal that prevents gas leakage and improves performance

Made of durable materials that can withstand high temperatures and pressures

Easy to install with the help of a professional mechanic

Compatible with several Yale models

Affordable and reliable

Applications

The 900005236 .020 Ring Set suits Yale forklifts. This ring set can replace worn or damaged rings in your cylinder or upgrade your forklift's performance.

Yale Forklift

Warranty Information

The 900005236 .020 Ring Set has a 12-month warranty covering materials or workmanship defects. If you encounter any problems with this ring set, please contact us, and we will provide you with a replacement or a refund.

Not Sure Will This Part Fits Your Equipment?

If you are not sure whether this ring set fits your forklift's engine, don't worry. We are here to help you find the right part for your equipment. You can contact us through any of the following channels:

Our friendly and knowledgeable staff will assist you with any questions or concerns. We will also provide a free quote and a fast delivery service.

Frequently Asked Questions

Q: How do I know if I need to replace my ring set?

A: You may need to replace your ring set if you notice any of the following signs:

Loss of power or performance

Excessive smoke or oil consumption

Low compression or misfiring

Engine knocking or rattling

Q: How do I measure the size of my ring set?

A: You can measure the size of your ring set by using a micrometer or a caliper. You need to measure the thickness and the diameter of each ring. The size of the ring set is usually expressed in inches or millimeters.

Q: How do I install the ring set?

A: You must follow your forklift's service manual instructions or consult a professional mechanic. The general steps are:

Remove the cylinder head and the piston from the engine block

Clean the cylinder and the piston from any dirt or debris

Install the new rings on the piston according to the order and orientation specified in the manual

Lubricate the rings and the cylinder with engine oil

Insert the piston into the cylinder and align it with the crankshaft

Reinstall the cylinder head and torque it to the specified value

Q: How often do I need to change my ring set?

A: The frequency of changing your ring set depends on several factors, such as:

The type and quality of fuel you use

The operating conditions and environment of your forklift

The maintenance schedule and practices of your forklift

Generally, you should inspect your ring set every 1000 hours of operation or every year, whichever comes first. You should replace your ring set if it shows signs of wear or damage.

Q: What are some tips to extend the life of my ring set?

A: You can extend the life of your ring set by following these tips:

Use clean and high-quality fuel that meets the specifications of your engine

Avoid overloading or overheating your forklift

Perform regular maintenance and tune-ups on your forklift

Check and adjust the valve clearance and ignition timing as needed

Frequently Bought Together

Customers who bought this item also bought: