Forklift Dimensions, Sizes, and Weight CapacityReading time: 04 min 49 sec. Table of Contents1. Summary2. Forklift Sizes 3. Forklift Weight Capacity 4. Forklift Dimensions 5. Choose Lift Parts Warehouse to buy Forklift Parts 6. Takeaways SummaryForklift dimensions, sizes, and weight capacity are all critical. The forklift is a piece of equipment that carries a load overhead, allowing a worker with a forklift to transfer freight from one place to another without lifting the items manually. The lift truck is similar to the forklift but has caterpillar tracks instead of tires. Today forklifts are not just used for moving pallets; they are forklift attachments that can be attached to forklifts, making them far more useful in the cargo handling industry. Today forklift attachments include but are not limited to; chainsaws, drills, saws, torches (welding), brooms, material support legs, and arms like outriggers or reach struts, etc. Forklift attachments reduce the number of personnel needed to complete a project. Forklift SizesForklift trucks come in many sizes; small walkie forklifts (1-7 metric tons capacity) up to large warehouse forklifts with over 100 mt (they can weigh 20 metric tons or more). The size of the forklift affects not only its ability to hold particular objects but also factors into which type of jobs it can do and what space it takes up when in use or parked. Forklifts come in several different types and styles for different purposes and tasks on the job site: counterbalanced trucks (most common), front-end loaders (folding and non-folding), and sit-down riders.

Forklift Weight CapacityWhen forklift fork extensions are attached, they can increase the forklift's capacity by over 100 mt if needed. The fork extension acts as a jib crane or outrigger boom that doesn't require set-up, which is time-consuming and highly skilled work. Many forklifts have attachments at their forks to handle specific cargo sizes, shapes, and weights. These forklift attachments are fork leveling systems, load backrests, side shift operators cabs, pallet forks, etc. When forklifts are used in high-temperature environments, it is essential to remember when selecting forklift accessories for materials handling. For example, the paint on an aluminum mast starts to bubble at approximately 98 degrees Celsius. The forklift mast is a point of high heat, and this forklift attachment will need to have cooling measures put in place. Forklift operators need to know the forklift's capacity to move cargo safely throughout their working day without the fear of overloading the forklift forks, mast, or attachments. Using a forklift at full capacity increases the risk that something will go wrong from tire blowouts, overheating forklift motors up to complete structural collapse/failure, which could be hazardous for personnel and cargo alike. Forklifts come with manuals that include forklift weight capacities and other important information such as safety warnings, maintenance tasks, etcetera.

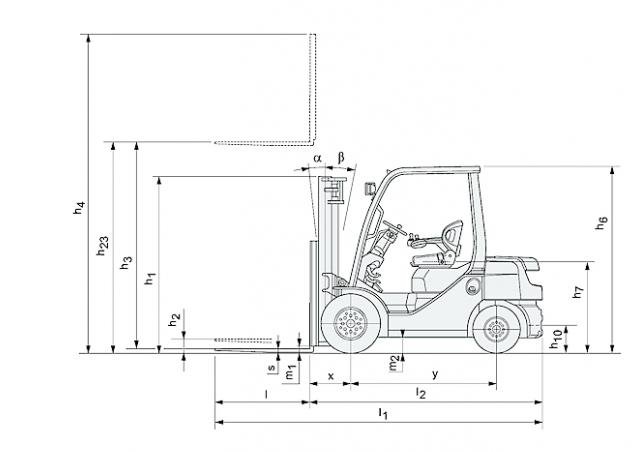

Beware of forklift companies and forklift operator training centers, forklift fork extensions. At the same time, they look attractive to employers, and forklift operators can be hazardous due to the load swaying created when moving an extended fork. This forklift accessory should only be used under very safe conditions, such as inside a forklift factory environment with strict supervision from trained forklift operators. Forklift dimensionsForklift dimensions address the following:

Why choose Lift Parts Warehouse to buy Forklift Parts?Why should you order from Lift Parts Warehouse? What's so special about us?

Takeaways

|

First Order Special

GET 5% OFF

On Your First Purchase!

Use this discount code

5PERCENTOFF

note: One redemption per account/IP address only