Forklift Order PickerReading time: 04 min 46 sec. Table of Contents1. Summary2. What is an Order Picker 3. Order Picker Manufacturers 4. Order Picker Job Occupation 5. Order Pickers Workers 6. Forklift Order Picker Operator 7. Tipping or Overturning 8. Fulcrum Point Diagram 9. Choose Lift Parts Warehouse to buy Forklift Parts 10. Takeaways SummaryForklift order pickers are an important part of the workforce in many industries. They are responsible for picking products from shelves and bringing them to a designated point. There are many different forklift order pickers’ types, each with its own unique capabilities. This blog post will overview order pickers, their types, operator requirements, and other configuration and technical settings. At Lift Parts Warehouse, we offer a wide variety of forklift parts and accessories to help you keep your forklift in top condition. We also have a team of experts available 24/7 to answer any questions you may have about maintaining or repairing your forklift. Give us a call today to learn more about our products and services! What is an Order Picker?An order picker is a forklift truck specifically designed in warehouses and other commercial storage facilities. It can lift, lower, push or pull items across a warehouse floor. These forklifts transport materials from one place to another within a warehouse or distribution center during picking, packing, loading, and unloading. They typically have an operator platform that allows the operator to stand while picking orders and a handle or tiller for steering. Forklifting requires the operator to follow accurately the written safety rules that will ensure the safe operation of the equipment. It has two different types: the electric forklift and the diesel forklift. The diesel forklifts are heavier than the electric ones, but they offer more power, and their productivity rate is higher than that of an electric model.

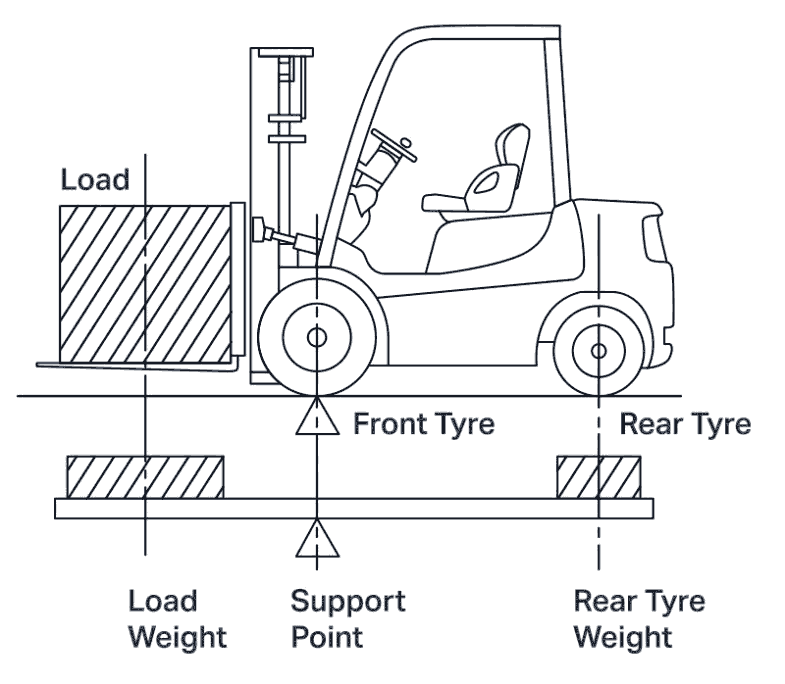

Order Picker ManufacturersForklift order pickers manufacturers make Forklifts designed according to every type of application needed for a specific industry, such as Forklift Material Handling Vehicles (MHEV). According to data from the American Trucking Association (ATA), more than 3 million registered commercial vehicles such as Forklifts in 2010. They have been around since the early 1950s with a wide range of applications, from being used as material handling equipment to being used as an industrial truck. Order Picker Job OccupationOrder picker jobs are available for people who want forklift certification and get into this industry, especially if you're already experienced in operating forklifts. Order Pickers WorkersOrder pickers workers use forklifts to carry items within warehouses or distribution centers. Forklifts must obey all these rules when operating a Forklift, including going through controlled access zones and warning signals. Forklifting requires the operator to follow accurately the written safety rules that will ensure the safe operation of the Forklift. They are in charge of loading and unloading before, during, and after the stock is moved to another place in the warehouse. Forklift Order Picker OperatorOrder picker operators operate Forklift Trucks, also known as Forklift Material Handling Vehicles (MHEV). Forklift trucks enable workers to efficiently move materials around a warehouse or distribution center. Forklifts have been around since the early 1950s with a wide range of applications, from being used as material handling equipment to being used as an industrial truck. The fulcrum point on a forklift is about one-third of the way from the front of the truck to the back near where the forks are attached. It is also called a "jaw point" because of its teardrop shape. The fulcrum point allows for a stable, level platform for lifting and carrying objects.

About two-thirds of load weight will be carried at the jaw area (fulcrum), while much less weight will be moved closer to the rear axle (tongue). When operating an empty forklift truck, it should be used in much smaller radius curves than when loaded. This is because it can tip or lose stability if too sharp of a turn is made with an empty truck. A fulcrum point near the middle of a forklift truck and rear axle allows it to turn easier than if a fulcrum was placed closer to the front of the forklift. A fulcrum point too close to the front would also cause a loss of stability but is far less likely due to more weight at that end of the forklift than at the fulcrum. Tipping or OverturningOne reason for an overturning accident is attempting a "turn-on-a-dime" maneuver when it isn't possible. This can result in hitting another object with one or more forks and tipping over. Another contributing factor in overturns is not approaching a tight area (2:1 ratio) correctly and turning too sharply or too quickly. Fulcrum Point DiagramThe fulcrum is in the center of the diagram in red, with the fulcrum in green representing it near the rear. It is next to where the forks are attached and shifts back slightly when one side of the forklift is pushed down further than the other causing it to lean towards the driven axle. The driven axle fulcrum point is called the tongue fulcrum because of its shape. This fulcrum must be even with front fulcrums when forks touch the ground so that forklift can lift evenly off of driven tires for best stability when carrying a load. Forklift operator seat must also be level at fulcrums for a most comfortable ride and best control over the forklift.

Why choose Lift Parts Warehouse to buy Forklift Parts?At Lift Parts Warehouse, you'll receive an exceptional customer experience. We have forklift experts on staff to answer your questions by phone, email, or live chat so that you know everything you order is the right part for your machine. If there's anything you'd like to ask before buying, give us a shout! Takeaways

|

First Order Special

GET 5% OFF

On Your First Purchase!

Use this discount code

5PERCENTOFF

note: One redemption per account/IP address only